Capabilities

Transforming Metal, Crafting Excellence

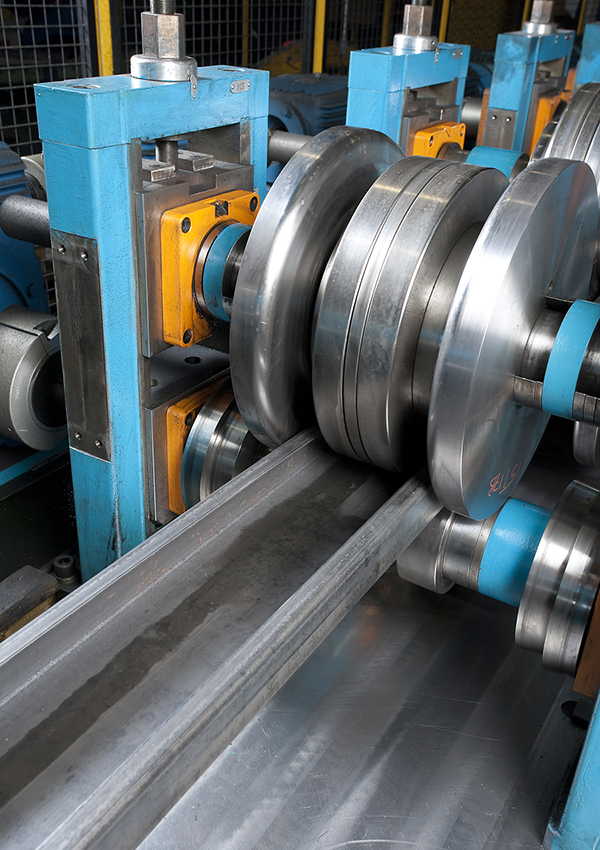

At Cargowall, we combine cutting-edge technology with our expertise to deliver high-quality roll formed parts tailored to your specific needs. Our advanced roll forming capabilities enable us to provide innovative and efficient solutions across various industries including Transportation, Infrastructure, Window & Door, Greenhouse, Solar, Mining, and Agriculture.

Roll Forming Expertise

Custom Roll Forming: Our custom roll forming services bring your design to life with precision and quality, ensuring each product adheres to the highest standards.

Standard Roll Forming: Our standard profiles cover a broad spectrum of sizes and shapes, serving diverse market needs with optimal quality and cost-effectiveness. Many of these pieces are stocked and have a short turnaround time for our customers.

Materials

Vast Material Selection: We process a wide range of ASTM steel alloys including stainless, HSLA, hot roll, cold roll, galvanized and galvanneal, aluminum, & pre-painted metals, ensuring our capability to meet the varied demands of our clients.

Material Thickness: Our mills and presses can handle material thicknesses from 0.010” to 0.250”, enabling us to serve a variety of industrial requirements.

Industries Served

From Transportation to Solar, we serve a multitude of industries with our adept roll forming solutions. Below is a summary of current industries served.

Quality Assurance

Dedicated to Quality: Our commitment to quality is evident through our stringent quality control measures and adherence to industry standards. We work with our customers to understand their unique needs, documentation and packaging requirements.

Value-Added Services

Design & Prototyping: Our experienced engineers work with you from design to prototyping, ensuring the final product meets your specifications.

Assembly & Finishing: We offer comprehensive assembly and finishing services, delivering products that are ready for immediate use.

Inventory Management: Our inventory management solutions streamline your supply chain, enhancing efficiency and reducing costs.

Logistical Support

Flexible Delivery Options: Choose from a range of delivery options, designed to ensure your product arrives when and where you need it.

Customer Support

Dedicated Service: Our team is dedicated to providing unparalleled customer service, ensuring your needs are met promptly and effectively. Communication is key at Cargowall.

Technical Support: Rely on our technical support team for assistance with design, material selection, and troubleshooting.